SyBridge Studio

Design for Manufacturing Analysis, Powered by AI

Engineer-informed. AI-powered. Design-focused.

SyBridge Studio is our easy-to-use design optimization platform that provides instant Design for Manufacturing (DFM) feedback and cost-saving insights that will streamline your part design and manufacturing processes with the power of AI.

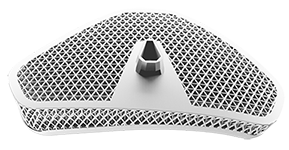

Optimize your part designs for 3D printing, CNC machining or injection molding with the power of AI

Discover cost-saving insights with Design to Cost (DTC) feedback to reduce production costs and stay within budget

Keep your part designs organized and accessible for quick comparison and rapid iteration

Experience seamless integration with our digital manufacturing platform, SyBridge On-Demand

SyBridge Studio Sneak Peek

- Create your free account

- Upload your 3D part files to SyBridge Studio

- Select a process and material

- Enter your specifications

- Get an instant DFM analysis of your design

- Place your order in SyBridge On-Demand

Support for 3D Printing, CNC Machining & Injection Molding

SyBridge Studio offers extensive process-specific DFM checks and cost-optimization feedback across 3D printing, CNC machining and injection molding — all of the technologies we support in SyBridge On-Demand.

From identification of critical manufacturability issues to potential aesthetic concerns, our AI-powered DFM checks ensure that your parts will result exactly as you intend.

Select each dropdown below to learn more about all of the DFM checks we run for each manufacturing process.

3D Printing DFM Checks

| DFM Check | DLS | MJF | FDM | SLA |

|---|---|---|---|---|

| Supported Surfaces | ||||

| Watertightness | ||||

| Minimum Process Resolution | ||||

| Inadequate Venting | ||||

| Trapped Material | ||||

| Regions Needing Venting | ||||

| Partially Vented Regions | ||||

| Thick Walls | ||||

| Thin Walls | ||||

| Feature Size | ||||

| Surface Imperfections | ||||

| Part Aspect Ratio | ||||

| Multiple Body Detection | ||||

| Part Unit Selection | ||||

| Part Size |

CNC Machining DFM Checks

| DFM Check | |

|---|---|

| Thin Walls | Thin walls that are at a high risk of deformation, poor surface finish or the tool breaking through the wall during manufacturing |

| Sharp Edges or Corners | Sharp concave corners: Sharp internal (concave) corners that require specialized tools, increasing cost and lead time |

| Standard Hole Sizes | Non-standard hole sizes that can increase costs due to longer machine times |

| Part Aspect Ratio | High aspect ratios — large differences between overall part dimensions — that may cause warpage |

| Multiple Body Detection | Multiple parts detected in one 3D file; parts must be uploaded individually for proper assessment |

| Deep Pockets or Slots | Deep pockets or slots that may pose a risk in manufacturing efforts or be unreasonable to manufacture with CNC |

| Surface Contouring | Requires a large amount of contouring that takes more time to machine, increasing cost |

| Low Material Utilization | Requires significant material removal that takes more time to machine, increasing cost |

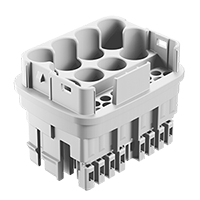

Injection Molding DFM Checks

| DFM Check | |

|---|---|

| Thick Walls | Thick walls that may increase cooling time or result in short shots |

| Thin Walls | Thin walls that may experience issues with molding, which can result in short shots |

| Sharp Edges or Corners | Sharp features that must be eased through fillets to ensure proper molding |

| Draft Angle | Insufficient draft in the direction of pull, which may lead to damage of the part or tool |

| Multiple Body Detection | Multiple parts detected in one 3D file; parts must be uploaded individually for proper assessment |

| Thin Steel | Regions in your part design that will result in thin, elongated sections of steel in the injection molding tool, increasing the likelihood of fractures during manufacturing or operation |

Enhanced DFM Analysis for Injection Mold Tooling

Ensuring manufacturability is important when you’re designing parts for any production process, but when you’re manufacturing parts by the thousands — or hundreds of thousands — it’s critical.

SyBridge Studio provides a set of DFM checks and recommendations specifically for injection molding, offering additional insights about your tooling in order to optimize part aesthetics and provide transparency into the aspects of your design that impact tooling costs.

Engineer-backed, AI-powered DFM Analysis Directly From the Manufacturer

287,670

Part Designs

Analyzed

200+

Engineering &

Technical

Professionals

18+

Production

Facilities

Discover what a difference instant DFM checks and cost-optimization guidance directly from the manufacturer can make.